Applied industries:

1.High-Precision Liquid Level Ranging: It is applicable to the liquid level measurement of tanks, the liquid level measurement of sewage wells, underground garages, large reservoirs, water storage tanks, sewage ditches, underground pipe network channels, and the detection of urban water supply or waterlogging during flood seasons (such as the monitoring of low-lying areas and drainage outlets). It also supports auxiliary water treatment operations, as well as the monitoring of urban water supply and sewage discharge.

2.Obstacle Avoidance Applications: Obstacle avoidance for intelligent robots, Obstacle avoidance for sweeping robots, etc.

3.High-Precision Object Distance Measurement;

Comparison Between Millimeter wave Ranging Radar Sensor and Other Ranging Sensors:

| Ranging performance | Millimeter wave radar | Ultrasonic | Infrared | Laser |

| High accuracy | √ | √ | X | X |

| Smaller Blind Zone | √ | X | √ | X |

| Can Penetrate Water | X | X | √ | √ |

| High consistency | √ | X | X | X |

| Not susceptible to interference from signals in the same frequency band | √ | X | X | X |

| Not susceptible to interference from lighting environments | √ | √ | X | X |

| Not susceptible to interference from coverage by dirt and other substances | √ | √ | X | X |

Features:

1.Non-contact measurement method, not easily corroded by sewage, high precision, high stability, and high resolution

2Low Power Consumption, Ultra-Small Size, Strong Anti-Interference, Good Stability, and Easy Maintenance

3.Strong Penetrability: It is not affected by environments such as heavy fog, dust, and thick smoke.

4.Easy Integration into Embedded Systems and Compatibility with Most RTU Communication Protocols on the Market.

5.Built-in Temperature Sensor with Dual Temperature Compensation.

6.Fully Sealed IP67 High-Grade Waterproof Design.

7.Simple Structure and Small Size, Ideal for Installation and Maintenance in Small Channels.

8.Suitable for Low Dielectric Constant Measurement

9.Small Beam Angle, Concentrated Energy, Stronger Anti-Interference Capability, Greatly Improving Measurement Accuracy and Reliability

10High Signal-to-Noise Ratio, Smaller Measurement Blind Zone, Shorter Wavelength, and Excellent Performance in Small Volume Measurement.

11.Adopting a pulse coherent operating mode, it can be installed in various metal or non-metallic containers, and causes no harm to the human body or the environment.

12.Easy to install, can be installed without drilling holes, with good concealment and no impact on appearance.

13.Supports Output Types Including RS485 (Modbus), UART (TTL), 0~10V, and 4-20mA.

14.Equipped with a serial port module for convenient on-site debugging and testing.

15.Equipped with Host Computer Software, Enabling Parameter Reading and Setting, Raw Data and Measurement Data Viewing, and Firmware Updates Without Disassembly.

Want to know more ?

Email us: sales@zegoo.net or Leave a message Submit

Technical details:

| Interface | RS485 | RS485+0~10V | RS485+4~20mA | UART(TTL) |

| Measuring range | A | 0.1~3m、0.1~7m、0.2~12m | ||

| B | 0.03~3m、0.05~7m、0.1~12m, 0.2~17m、0.2~21m | |||

| C | 0.2~30m、0.2~40m、0.2~50m | |||

| Power | 3.3-5.5VDC、5-24VDC | |||

| Consumption | ≤180mW | ≤180mW | ≤180mW | ≤180mW |

| Accuracy | ±1mm | |||

| Resolution | 1mm | |||

| Beam angle | 5°,10°,20° | |||

| Working temperature | ﹣40℃~+80℃(model A\C),﹣40℃~+100℃(model B) | |||

| Storage temperature | ﹣45℃~+85℃ | |||

| Working humidity | ≤95% | |||

|

Measurement interval |

50ms~10s adjustable(There are differences among different measuring ranges) | |||

|

Communication protocol |

ModbusRTU、ASCII | |||

| IP grade | IP67(M30),IP68(M39) | |||

|

Power supply protection |

Overcurrent and reverse connection protection | |||

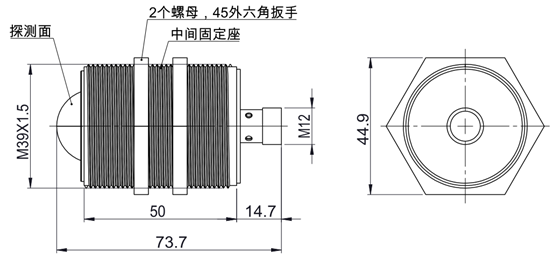

| Volume | 36×36×54mm(M30*1.5)、45×45×74mm(M39*1.5) | |||

| OLED display | Optional | |||

| Frame material | Copper-plated nickel, ABS, Stainless steel (corrosion-resistant), PA12 | |||

| Baud rate | 2400~256000 adjustable,default 115200 | |||

|

Measurement output |

Timed measurement output, Query output | |||

| Program function | Supports parameter modification and radar echo graph viewing via the host computer | |||

Drawings: